Sprockets Dùbailte-phàirce a rèir Inbhe Àisianach

NK2040SB

| SPROCAICHEAN | mm |

| Leud fiacail (T) | 7.2 |

| SLABHAIR | mm |

| Raon (P) | 25.4 |

| Leud a-staigh | 7.95 |

| Rolair Φ (Dr) | 7.95 |

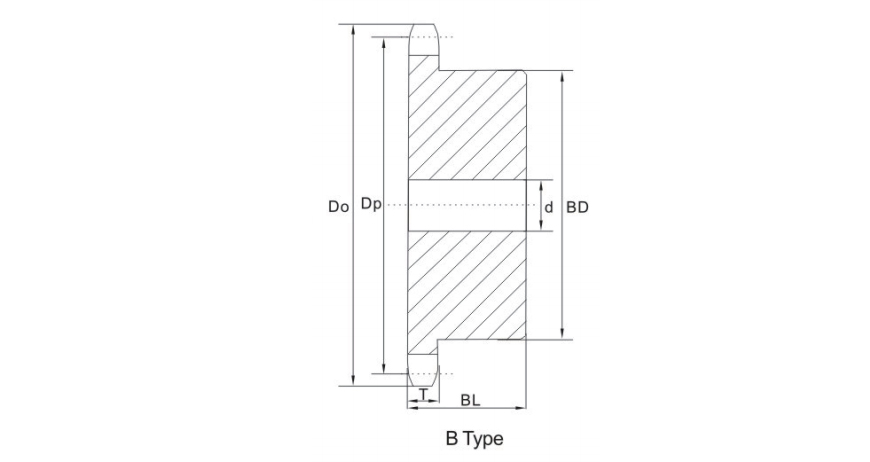

| Seòrsa | Fiaclan | Do | Dp | Leamh | BD | BL | Cuideam kg | Stuth | ||

| Stoc | Min | Max | ||||||||

| NK2040SB | 6 1/2 | 59 | 54.66 | 13 | 15 | 20 | 35 | 22 | 0.20 | C45 Soladach |

| 7 1/2 | 67 | 62.45 | 13 | 15 | 25 | 43 | 22 | 0.30 | ||

| 8 1/2 | 76 | 70.31 | 13 | 15 | 32 | 52 | 22 | 0.42 | ||

| 9 1/2 | 84 | 78.23 | 13 | 15 | 38 | 60 | 25 | 0.61 | ||

| 10 1/2 | 92 | 86.17 | 14 | 16 | 46 | 69 | 25 | 0.82 | ||

| 11 1/2 | 100 | 94.15 | 14 | 16 | 51 | 77 | 25 | 0.98 | ||

| 12 1/2 | 108 | 102.14 | 14 | 16 | 42 | 63 | 25 | 0.83 | ||

NK 2050SB

| SPROCAICHEAN | mm |

| Leud fiacail (T) | 8.7 |

| SLABHAIR | mm |

| Raon (P) | 31.75 |

| Leud a-staigh | 9.53 |

| Rolair Φ (Dr) | 10.16 |

| Seòrsa | Fiaclan | Do | Dp | Leamh | BD | BL | Cuideam kg | Stuth | ||

| Stoc | Min | Max | ||||||||

| NK2050SB | 6 1/2 | 74 | 68.32 | 14 | 16 | 25 | 44 | 25 | 038 | C45 Soladach |

| 7 1/2 | 84 | 78.06 | 14 | 16 | 32 | 54 | 25 | 0.55 | ||

| 8 1/2 | 94 | 87.89 | 14 | 16 | 45 | 65 | 25 | 0-76 | ||

| 9 1/2 | 105 | 97.78 | 14 | 16 | 48 | 73 | 28 | 1-06 | ||

| 10 1/2 | 115 | 107,72 | 14 | 16 | 48 | 73 | 28 | 1.16 | ||

| 11 1/2 | 125 | 117.68 | 16 | 18 | 48 | 73 | 28 | 1.27 | ||

| 12 1/2 | 135 | 127.67 | 16 | 18 | 48 | 73 | 28 | 1.40 | ||

NK 2060SB

| SPROCAICHEAN | mm |

| Leud fiacail (T) | 11.7 |

| SLABHAIR | mm |

| Raon (P) | 38.10 |

| Leud a-staigh | 12.70 |

| Rolair Φ (Dr) | 11.91 |

| Seòrsa | Fiaclan | Do | Dp | Leamh | BD | BL | cuideam kg | Stuth | ||

| Stoc | Min | Max | ||||||||

| NK2060SB

| 6 1/2 | 88 | 81.98 | 14 | 16 | 32 | 53 | 32 | 0.73 | C45 Soladach

|

| 7 1/2 | 101 | 93.67 | 16 | 18 | 45 | 66 | 32 | 1.05 | ||

| 8 1/2 | 113 | 105.47 | 16 | 18 | 48 | 73 | 32 | 133 | ||

| 9 1/2 | 126 | 117.34 | 16 | 18 | 55 | 83 | 40 | 203 | ||

| 10 1/2 | 138 | 129.26 | 16 | 18 | 55 | 83 | 40 | 2.23 | ||

| 11 1/2 | 150 | 141.22 | 16 | 18 | 55 | 80 | 45 | 256 | ||

| 12 1/2 | 162 | 153.20 | 16 | 18 | 55 | 80 | 45 | 281 | ||

Bidh sprocaidean slabhraidh giùlain dà-phàirce gu tric air leth freagarrach airson àite a shàbhaladh agus bidh beatha caitheamh nas fhaide aca na sprocaidean àbhaisteach. Freagarrach airson slabhraidhean fada-phàirce, tha barrachd fhiaclan aig sprocaidean dà-phàirce na sprocaid àbhaisteach den aon trast-thomhas cearcall-phàirce agus bidh iad a’ sgaoileadh caitheamh gu cothromach thar nam fiaclan. Ma tha an t-slabhraidh giùlain agad co-chòrdail, is fhiach beachdachadh air sprocaidean dà-phàirce gu cinnteach.

Tha sprocaid airson slabhraidhean rolair dà-phàirce rim faighinn ann an dealbhadh aon-fhiaclach no dà-fhiaclach. Tha an aon ghiùlan aig sprocaid aon-fhiaclach airson slabhraidhean rolair dà-phàirce ri sprocaid àbhaisteach airson slabhraidhean rolair a rèir DIN 8187 (ISO 606). Air sgàth pàirce slabhraidh nas motha nan slabhraidhean rolair dà-phàirce, tha e comasach seasmhachd a mheudachadh le atharrachaidhean fiaclach.

Tha an aon trast-thomhas agus leud a-muigh aig sprocaidean seòrsa rolair àbhaisteach ris an fheadhainn le aon phàirce, dìreach le pròifil fiacail eadar-dhealaichte gus leigeil leis an t-slabhraidh suidhe gu ceart. Air àireamhan fiaclan cothromach, chan eil na sprocaidean seo a’ ceangal ris an t-slabhraidh ach air gach fiacail eile leis gu bheil dà fhiacail gach pàirce. Air àireamhan fiaclan neònach, chan eil fiacail sam bith a’ dol an sàs ach air gach cuairt-chuairt eile, agus tha sin gu dearbh a’ meudachadh beatha an sprocaid.